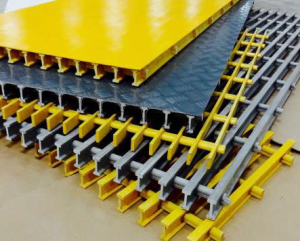

FRP / GRP Grating

Fiberglass reinforced plastic grating (also known as FRP grating / glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. FRP grating is a structural product that can be weight-bearing between spans.

FRP/GRP PROFILES SOLUTIONS TO ALL INDUSTRIES

FRP/GRP materials are durable and tough material which is regard as replacement of wood and steels. FRP/GRP structural profiles and gratings are commonly seen in nowadays – handrails, stair treads, insulation ladders and many other industrial applications.

Chemical Processing

Chemical Processing are full of corrosion, including acid, alkali, organic solvent, salt and many other gas and liquid media. During production, there need lots of platforms and protective measures for safe and efficient working.

Polyester resin type FRP/GRP profiles and gratings are ideal choice to solve all these problems. And they are more and more accepted by chemical industries in native or abroad.

WHY CHOOSE FRP/GRP PRODUCTS

- Perfect Chemical Stability. Won’t rust and corrosion like galvanized or aluminum products.

- Strong but lightweight. Same loading capacity but 1/3 weight of steels.

- Easy installation & fabrication. Lightweight FRP/GRP makes installation and fabrication easy and fast.

- Little maintenance. No need cleaning or painting to save maintenance costs.

- Anti-aging performance. UV inhibitors are added for anti-aging even in harshest environments.

- Long term durability. More than 35 years lifespan is worthy for your choice.

Water & Sewage Treatment

Waste waters will be purified through physical, chemical and biological methods to reduce pollution and make full of water resources.

The original steel devices are easy corroded by the chemical agents and they need lots of maintenance costs like painting.

FRP/GRP materials including FRP/GRP profiles and gratings are ideal materials for water and waste water treatment industries due to its excellent chemical and physical stability.

WHY CHOOSE FRP/GRP PRODUCTS

- Perfect Chemical Stability. Won’t rust and corrosion like galvanized or aluminum products.

- Humidity resistance. No shrinking or deformation even being exposed to the corrosive waters for long time.

- Strong but lightweight. Same loading capacity but 1/3 weight of steels.

- Easy installation & fabrication. Lightweight FRP/GRP makes installation and fabrication easy and fast.

- Little maintenance. No need cleaning or painting to save maintenance costs.

- Anti-aging performance. UV inhibitors are added for anti-aging even in harshest environments.

- Long term durability. More than 35 years lifespan is worthy for your choice.

Electricity & Power

In the electricity and power industries, insulation is most important to secure workers’ safe and efficient production. Traditional steel cable management and operation tools are not safe and even dangerous to be used in high risk electricity and power industries.

FRP/GRP are fiber reinforced plastic, which has excellent insulating and humidity resistance performance. So the FRP/GRP profiles and grating s are widely used in electrical power engineering.

WHY CHOOSE FRP/GRP PRODUCTS

- Excellent insulating performance. Secure workers’ safe and guarantee efficient production.

- Humidity resistance. No shrinking or deformation even being exposed outdoors for long time.

- Strong but lightweight. Same loading capacity but 1/3 weight of steels.

- Anti-aging performance. UV inhibitors are added for anti-aging even in harshest environments.

- Easy installation & fabrication. Lightweight FRP/GRP makes installation and fabrication easy and fast.

- Little maintenance. No need cleaning or painting to save maintenance costs.

- Long term durability. More than 35 years lifespan is worthy for your choice.

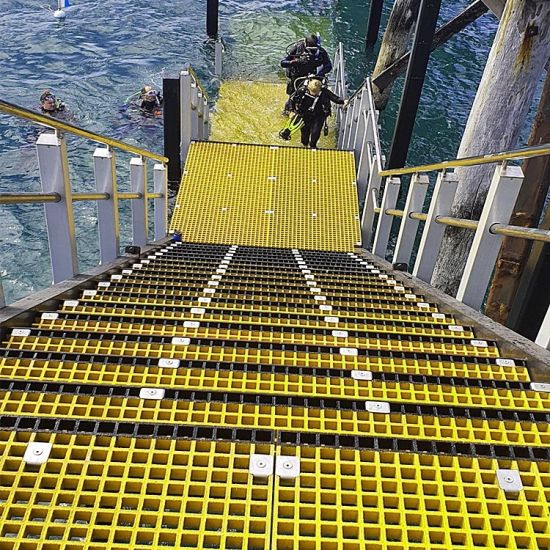

Oil & Gas

In oil drilling and natural gas extraction processing, offshore rigs are exposed to salt water and salt airs for long times. Common steel materials are easy corroded in these harsh environments and need much more maintenance costs.

FRP/GRP likes FRP/GRP profiles and gratings are ideal choice to solve all these problems. And they are more and more accepted by chemical industries in native or abroad.

WHY CHOOSE FRP/GRP PRODUCTS

- Perfect Salty Resistance. Won’t rust and corrosion like galvanized or aluminum products.

- High & stable loading capacity. It has same and superior loading capacity in more than 35 years life.

- Humidity resistance. No shrinking or deformation even being exposed to the salty water or air for long time.

- Strong but lightweight. Same loading capacity but 1/3 weight of steels.

- Easy installation & fabrication. Lightweight FRP/GRP makes installation and fabrication easy and fast.

- Little maintenance. No need cleaning or painting to save maintenance costs.

- Long term durability. More than 35 years lifespan is worthy for your choice.

- Safe Structure. Handrails and anti-slipping platforms and stairs can guarantee safe working.

Mechanical Engineering

In the mechanical engineering, FRP/GRP profiles play important roles due to its good hardness, high loading capacity and flexible structures. They are widely used in machine guarding and structure support applications.

WHY CHOOSE FRP/GRP PRODUCTS

- Good hardness. Vinyl ester resin supply excellent mechanical property.

- High loading capacity. Support structures well for long terms.

- Flexible structures. Customized shapes can satisfy different machine part requirements.

- Excellent insulating performance. Secure workers’ safe and guarantee efficient production.

- Humidity resistance. No shrinking or deformation even being exposed to the salty water or air for long time.

- Strong but lightweight. Same loading capacity but 1/3 weight of steels.

- Anti-aging performance. UV inhibitors are added for anti-aging even in harshest environments.

- Easy installation & fabrication. Lightweight FRP/GRP makes installation and fabrication easy and fast.

- Little maintenance. No need cleaning or painting to save maintenance costs.

- Long term durability. More than 35 years lifespan is worthy for your choice.

Building & Construction

In the building and constructions, there need lots of structure supporting, walkways and cable management.

The FRP/GRP is more and more popular all over the world, and it is regard as replacement of wood and steels because of its lightweight but strong structure. FRP/GRP profiles are widely used for support structures and FRP/GRP gratings are used in parks and other buildings are platforms and walkways.

WHY CHOOSE FRP/GRP PRODUCTS

- High Loading capacity. For structure supporting and heavy vehicles access.

- Humidity resistance. No shrinking or deformation even being exposed to the salty water or air for long time.

- Strong but lightweight. Same loading capacity but 1/3 weight of steels.

- Anti-aging performance. UV inhibitors are added for anti-aging even in harshest environments.

- Easy installation & fabrication. Lightweight FRP/GRP makes installation and fabrication easy and fast.

- Little maintenance. No need cleaning or painting to save maintenance costs.

- Long term durability. More than 35 years lifespan is worthy for your choice.